工艺验证方案

The following is one possible procedure of process validation the customer may employ.

It is necessary for the customer to determine his individual procedure as there are many

variables that can impact this process. This document is therefore intended for reference

purposes only.

以下是客户可能采用的一个评估生产过程的步骤。当有多种选择可以进行操

作时,客户有必要确定最适合自身情况的操作步骤。下面的文章供大家参考。

Process Validation: 评定操作过程

1. Assume all parts in the sample have not been cracked by a previous process.

假定所有零件试样在前一个操作步骤中都没有出现开裂的情况。

2. The press has been set up properly and the customer has decided on a proper reject limit.

压头安装正确,并且客户确定了一个适当的报废产品数量限制。

3. The customer should choose a statistically relevant sample size of a part to be evaluated (50 parts) from the same lot. Do not mix different parts.

客户应当选择统计上相关的试件数量(如50 个)并与相同批次的试件区分开。不要将零件弄混。

4. The test sample must remain intact without chance of mixing.

试件必须保持原状态不能弄混。

5. Run the samples through the press.

让试件通过压头。

6. Rejected parts must be numbered, marked with the punch location, and the signal must be stored with the number assigned to the reject. These should be kept separate.

即将报废的零件必须被计数并且标上冲压位置,相应的零件编号也将被存储起来。这些零件将被分开放置。

7. Accepted parts must also be kept separate.

留下的零件也将被单独放置。

8. All rejected parts must be inspected for cracks.One possible method is attached.

必须对所有即将报废的零件进行探伤。下面附上一种检测方法。

A sample of the accepted parts (10) is also evaluated by the method above.

由10 个可用零件组成的样品也同样用上面的方法进行评估。

10. If cracks are found in the accepted sample, the reject limits are lowered and the

test repeated.

如果在可用零件中也发现了裂缝,那么报废的限额将降低,测试将重新进

行。

11. The identification of cracked parts does validate the CiS01 hardware and software.

损伤零件的辨识恰恰证实了CiS01 硬件和软件所发挥的效用。

12. It is the customer’s responsibility to continually monitor the process collecting data and readjusting limits as the customer deems necessary.

在需要的时候客户有责任不间断的监视检测过程、收集相关数据、调整极值。

The following is one possible method of inspecting parts that have been rejected. The actual process must be developed by the customer in conjunction with his metallurgical department. This example is meant for reference only.

下面是一种可能使用的对即将报废零件进行探伤的方法。实际的操作过程应当由客户和他的金属加工部门共同研究决定。下面这个例子仅供参考。

Here are examples of two shafts that were rejected by the CiS.01 System.

下面以这两根已经被CIS.01 系统辨识并报废的钢轴作为实例。

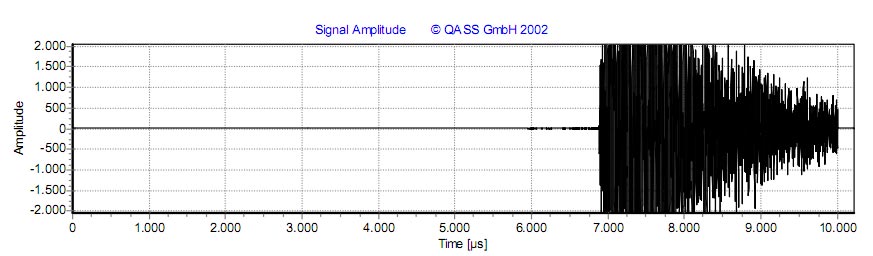

This Shaft had an energy level of 144 on the CiS.01.The actual signal signature is:

这根钢轴在CiS.01 系统中拥有的能量值是144。实际的信号形状如下:

This crack is approximately 12mm long and 2mm wide.

这道裂纹大约12mm 长2mm 宽。

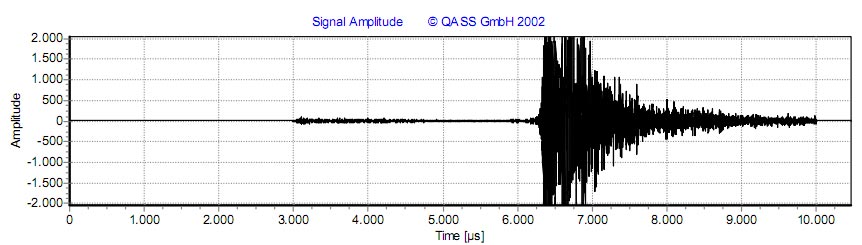

This Shaft had an energy level of 54 on the CiS.01.The actual signal signature is:

这根钢轴在CiS.01 系统中拥有的能量值是54。实际的信号形状如下:

This crack is approximately 4mm long and 1mm wide.

这道裂纹大约4mm 长1mm 宽。

The procedure that was used to identify these cracks is as follows:

常用的辨识该类裂纹的操作过程如下:

Step 1, the shafts were subjected to a 430 degree C oven for 2 hours to relieve surface tension.

步骤一:首先将轴放在430 摄氏度高温的炉中加热2 小时以释放其表面张力。

Step 2, the Shafts were cleaned with water then dried in a 50 degree C oven for 10 minutes.

步骤二:将轴浸入水中后放在50 度高温的路中10 分钟烘干。

Step 3, the shafts were covered with a dye penetrant (Helling, MET-L-CHK FBK-914 and left for 15 minutes at room temperature.

步骤三:将轴的表面涂上可染色的渗透剂并在室温下放置15 分钟。

Step 4, the excess penetrant was removed.

步骤四:多余的染色剂将被去除。

Step 5, the shafts were again allowed to dry for 10 minutes in a 50 degree C oven.

步骤五:再次将轴放在50 度的炉中烘干10 分钟。

Step 6, the developer is applied to the part.

步骤六:零件涂上显影剂。

Step 7, the shafts were inspected.

步骤七:对钢轴进行检测。

Please note that this method is detailed for reference only.

以上方法仅供参考。